Kent Corporation’s Steel Tube Manufacturing Process

From Raw Materials to Finished Products

As the leading experts in the strip-processing industry, we know what it takes to make a superior steel tube. Here’s an inside look at how our process and equipment leverage automation to gain efficiency and throughput and increase tube production quality.

Raw Materials

While our process doesn’t start here, this is where the quality starts. Quality steel tubing starts with the mining of raw, steel-grade materials: iron ore, coal and limestone. During this step, it’s important that the materials are free from impurities and non-metallic materials that can lead to defects.

Iron, Steelmaking & Casting Processes

Once mined, the iron ore, coal and limestone enter a blast furnace, where the intense heat and chemical reactions melt and purify the iron.

Now the iron is ready to be made into steel, using one of two methods: the Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF) method. During this step, iron is alloyed with manganese, nickel, chromium, carbon and vanadium to strengthen, harden and create a corrosion-resistant property.

When the steel is finally made, it’s time to be cast into billets or slabs. This ensures the steel is uniform, free of defects and ready to roll.

Roll Form Process

Accumulators

Here’s where Kent Corporation’s complete line of entry equipment comes in. The steel slabs are cut into master coils that are later slit into production coils for forming. Coming off an uncoiler they are wound around an accumulator. We offer both horizontal and vertical strip accumulators to fit the needs of your steel tube production line, saving both space and downtime. It’s easy to see why more than 1,000 companies choose Kent Corporation for their accumulators.

Sometimes the coil strips need to be manually moved with the help of a coil car or transitioned from an uncoiler to the end welder with the assistance of a peeler.

Coil End Welders

When you need a continuous process, an end welder is indispensable. As a must-have piece of equipment, the coil end welder joins coils quickly, precisely and securely with a full line of portable or stationary machines that offer TIG, MIG, plasma or laser welding options. Coil end welders combined with accumulators allow for continuous coil processing.

Flatteners

For thicker gauge coils, typically above 0.150”, flatteners are required prior to the end welder to prepare the strip prior to end welding. This increases your uptime by reducing the number of irregularities that could halt the production process. It also saves material, as it reduces the amount needed to be cut off the coil.

Tube Formation Process

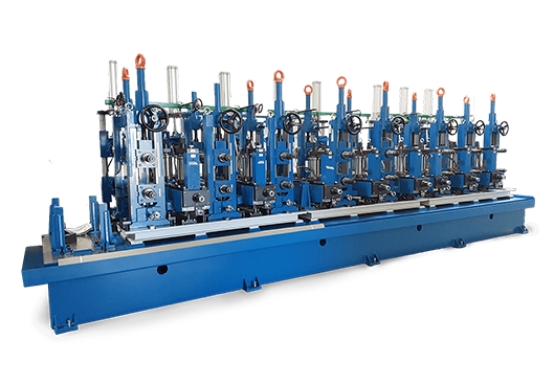

Tube Mill

After the strip entry system, the steel coils are ready to be formed. MTM Group’s tube mills can reliably and efficiently form tubes as quickly as 656 feet per minute depending on size.

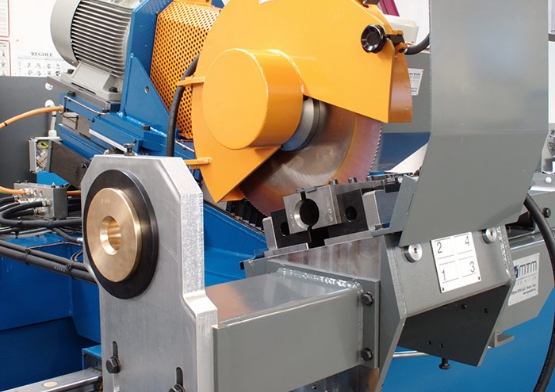

Precision Cut-Off

All tubes are cut to specific lengths using a flying cut-off saw or shear cutoff. These machines are robust and reliable.

Tube Finishing Process

Draw Bench

For precision sizing, the tubes come off the production line and are ready for the Cartacci Draw Bench. Here, they are automatically shaped for the exact diameter, length and thickness required.

Tube Straightener

Don’t waste your time and materials by rejecting deformed tubes. Instead, the Cartacci Straightener straightens the tube and makes the most of your materials, allowing you to meet any of your company’s lean manufacturing objectives.

Deburring Machine

After the cutting process the tube is ready to be deburred to ensure high quality tubing can be handled safely. At Kent Corporation, we provide both Roboburr and Burrmaster to meet your most demanding applications.

To learn how to choose the right finishing equipment for your tube production line, read this guide.

Learn More about the Tube Mill Process

Subscribe to our newsletter to learn more about the tube mill process and become an expert in all things in the strip processing industry.