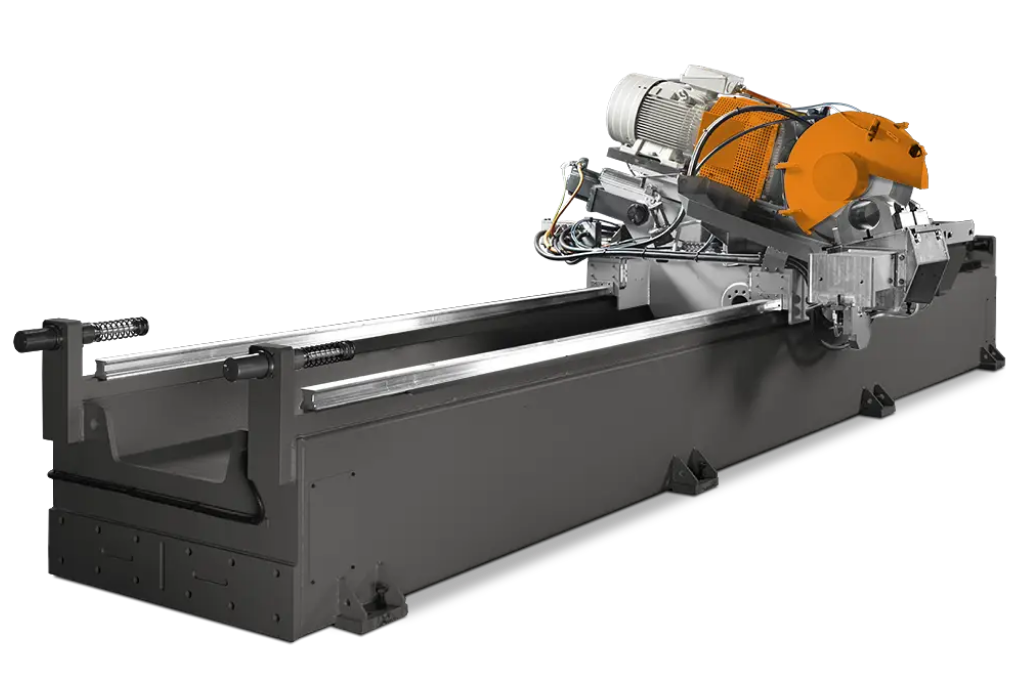

Tube Mill Flying Cut-Off

Machines

Cut your tubing with speed and precision. As an exclusive distributor of MTM flying cut-off saws, we’re proud to offer state-of-the-art cut-off machines to cut round or shaped steel tubing to specific lengths for a more precise cut.

When compared to flying shear cutoffs, these saws offer several advantages. Our MTM flying cut-off saw delivers a superior cut at a lower cost and requires less maintenance. While shears may have faster cutting times, the MTM saw is one of the fastest and most reliable options available in the market.

At Kent Corporation, we offer a wide range of tube cut-off machines to suit different requirements. Our selection includes single-blade cold saws (HSS and TCT), dual-blade orbital cold saws (Comby), friction saws, single-blade punch and double-knife (dimple-free) machines. To find the best solution for your tube mill, please reach out to our knowledgeable product specialists.

Benefits

Capabilities

Features

MTM Flying Cut-Off Saw Characteristics

| Model | Min. Diameter (IN) | Max. Diameter (IN) | WT Min. (IN) | WT Max. (IN) | Cutting Process | Tolerance | Max. Cuts | Max. Speed (FT/MIN) |

|---|---|---|---|---|---|---|---|---|

| TC400 RAD | - | - | 0.008 | 0.014 | P | ±0.012 | 500 | 394 |

| A25 SK | 0.236 | 1.1 | 0.008 | 0.047 | P | ±0.020 | 150 | 656 |

| A25 SC | 0.394 | 1 | 0.02 | 0.059 | C | ±0.039 | 50 | 591 |

| A50 CS | 0.394 | 1.5 | 0.02 | 0.1 | C | ±0.039 | 36 | 591 |

| A71 CS | 0.5 | 3.15 | 0.028 | 0.177 | C | ±0.039 | 30 | 591 |

| A71 FS | 0.5 | 3.15 | 0.028 | 0.236 | F | ±0.039 | 30 | 591 |

| A100 CS | 1.5 | 6 | 0.04 | 0.236 | C | ±0.059 | 25 | 394 |

| A100 FS | 1.5 | 6.615 | 0.04 | 0.315 | F | ±0.059 | 25 | 394 |

| A200 FS | 3 | 10 | 0.08 | 0.4 | F | ±0.100 | 15 | 262 |

| M&K1.5 | 0.236 | 1.5 | 0.02 | 0.079 | D | ±0.059 | 90 | 656 |

| M&K3 | 0.75 | 3 | 0.031 | 0.157 | D | ±0.059 | 60 | 591 |

| M&K5 | 1.2 | 5 | 0.059 | 0.236 | D | ±0.059 | 40 | 394 |

| A206 COMBY | 2.5 | 6.615 | 0.059 | 0.5 | COMBY | ±0.059 | 15 | 262 |

| A208 COMBY | 3 | 8.625 | 0.08 | 0.5 | COMBY | ±0.059 | 15 | 200 |

| Above sizes are general recommendations, please contact us to discuss your specific application. | ||||||||

| Model | Min. Diameter (MM) | Max. Diameter (MM) | WT Min. (MM) | WT Max. (MM) | Cutting Process | Tolerance (MM) | Max. Cuts | Max. Speed (m/min) |

|---|---|---|---|---|---|---|---|---|

| TC400 RAD | - | - | 0.2 | 0.3 | P | ±0.3 | 500 | 120 |

| A25 SK | 10 | 28 | 0.2 | 1.2 | P | ±0.5 | 150 | 200 |

| A25 SC | 10 | 25 | 0.5 | 1.5 | C | ±1.0 | 50 | 180 |

| A50 CS | 10 | 38 | 0.5 | 2.5 | C | ±1.0 | 36 | 180 |

| A71 CS | 12 | 80 | 0.7 | 4.5 | C | ±1.0 | 30 | 180 |

| A71 FS | 12 | 80 | 0.7 | 6 | F | ±1.0 | 30 | 180 |

| A100 CS | 38 | 152 | 1 | 6 | C | ±1.5 | 25 | 120 |

| A100 FS | 38 | 168 | 1 | 8 | F | ±1.5 | 25 | 120 |

| A200 FS | 76 | 254 | 2 | 10 | F | ±2.5 | 15 | 80 |

| M&K1.5 | 10 | 38 | 0.5 | 2 | D | ±1.5 | 90 | 200 |

| M&K3 | 19 | 76 | 0.8 | 4 | D | ±1.5 | 60 | 180 |

| M&K5 | 31 | 127 | 1.5 | 6 | D | ±1.5 | 40 | 120 |

| A206 COMBY | 63 | 168 | 1.5 | 12.7 | COMBY | ±1.5 | 15 | 80 |

| A208 COMBY | 76 | 219 | 2 | 12.7 | COMBY | ±1.5 | 15 | 60 |

| Above sizes are general recommendations, please contact us to discuss your specific application. | ||||||||

Cutting Process Legend:

| P | Punch |

| C | Cold Saw |

| F | Friction Saw |

| D | Dimple Free |

| COMBY | MTM Orbital Cold Saw Process |

Maintenance Support

Whether you need preventative or emergency maintenance for your coil processing equipment, you can count on Kent Corporation. We’ll be your partner for the long term.

Questions?

Contact Kent Corporation to learn more about the MTM Tube Mill flying cut-off saw.