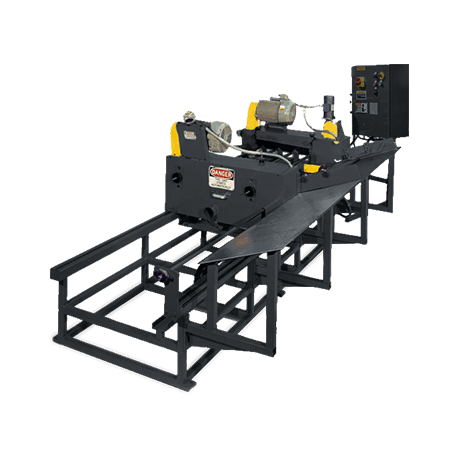

De-dimpling Machines

Improve the efficiency of your production process by adding a Buckeye or Loopco-style de-dimpling machine. During the finishing process, the de-dimpler will return the tube end to its original round shape, removing the dimple left by a shear cutoff.

The de-dimpling machines we offer have fast cycle times, quick set-up, automated length adjustment, and automated inline or offline dimple removal.

Contact our product specialists to find the best solution for your tube mill.