Linear Cage Forming Mills

Olimpia 80’s linear cage forming mills are at the forefront of innovative tube and profile production, offering exceptional flexibility and precision for either round or shaped profiles. Designed to handle a wide range of materials and dimensions, these mills enable efficient, high-speed production with minimal setup time. Their advanced design ensures uniformity and consistency across the entire production process, making Olimpia 80’s linear cage forming mills an essential asset for manufacturers seeking to enhance their output quality and efficiency. Each line is tailored to the application, allowing manufacturers to optimize their production lines with dedicated machinery that meets specific shape and dimension requirements efficiently and accurately.

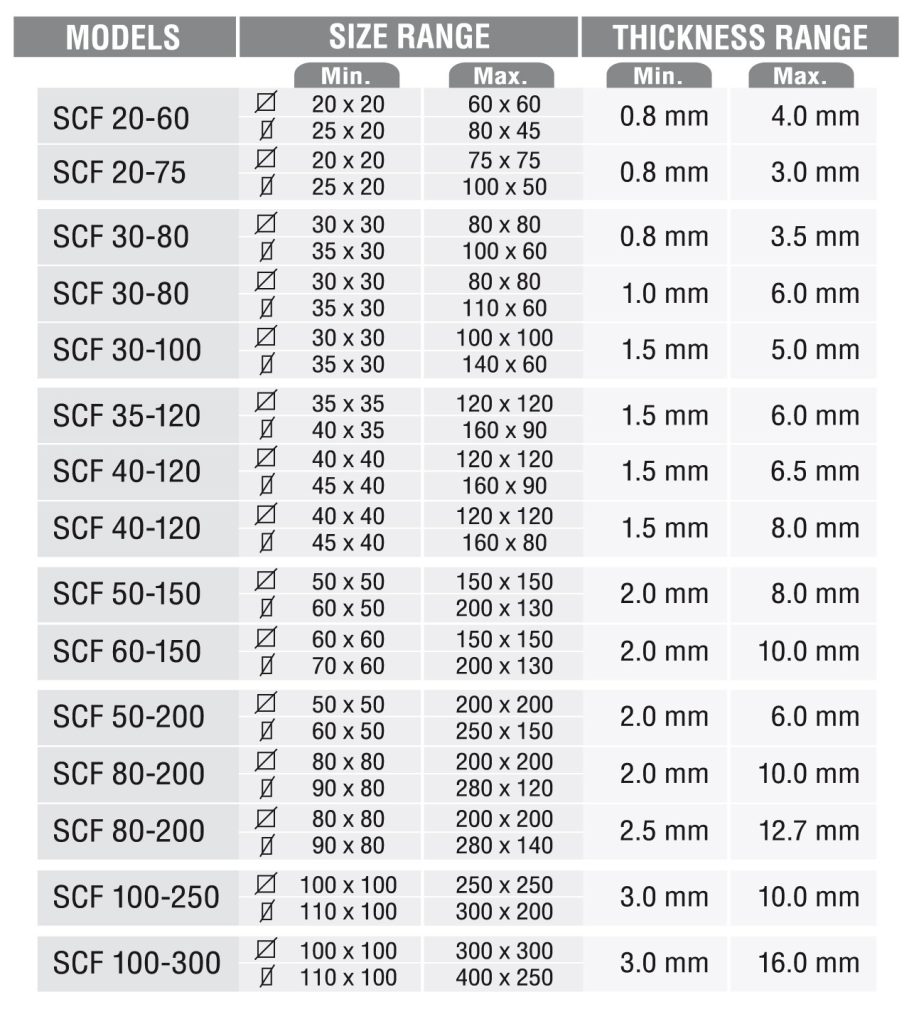

Carbon Steel Tube Mill General Specifications

Advantages

- Great flexibility and possibility of modify the tube dimension without any forming roll change for any size included into the mill size range

- Extreme reduction of mill set up time

- Elimination of cost for forming rolls

- Productivity increase and reduction of stock and relative costs

- Reduction of manpower thanks to the complete automatization of the mill operation and adjustments

- Minimal and easy maintenance

- Easy use of software for set up of any production parameter

- Display with automatic illustration of tube section for each production step

Advantages

- Great flexibility and possibility of modify the tube dimension without any roll change (in forming – welding – sizing – straightening) for any size included into the mill size range

- Extreme reduction of mill set up time

- Elimination of all cost for roll sets

- Increase of productivity and reduction of stock and relative costs

- Reduction of manpower thanks to the complete automatization of the mill operation and adjustments

- Minimal and easy maintenance

- Easy use of software for set up of any production parameter, including tube angle radius

- Display with automatic illustration of tube section for each production step

Benefits

Specialty Tube Mills

As a tube mill manufacturer, Olimpia 80 offers specialty tube mills to fit your unique application. Explore the available options, and contact Kent Corporation to request a quote.

Maintenance Support

Whether you need preventative or emergency maintenance for your tube mill equipment, you can count on Kent Corporation. We’ll be your partner for the long term.

Questions?

Contact Kent Corporation to learn more about our Olimpia 80 tube mills.